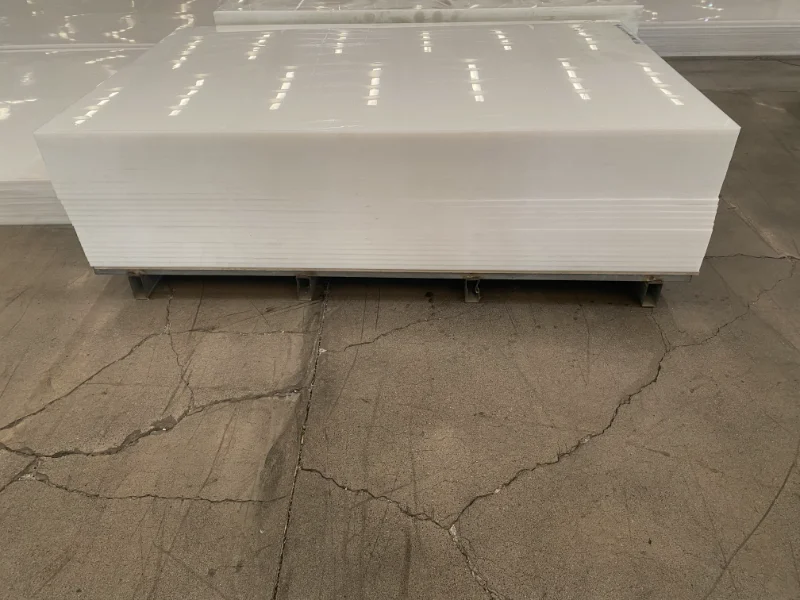

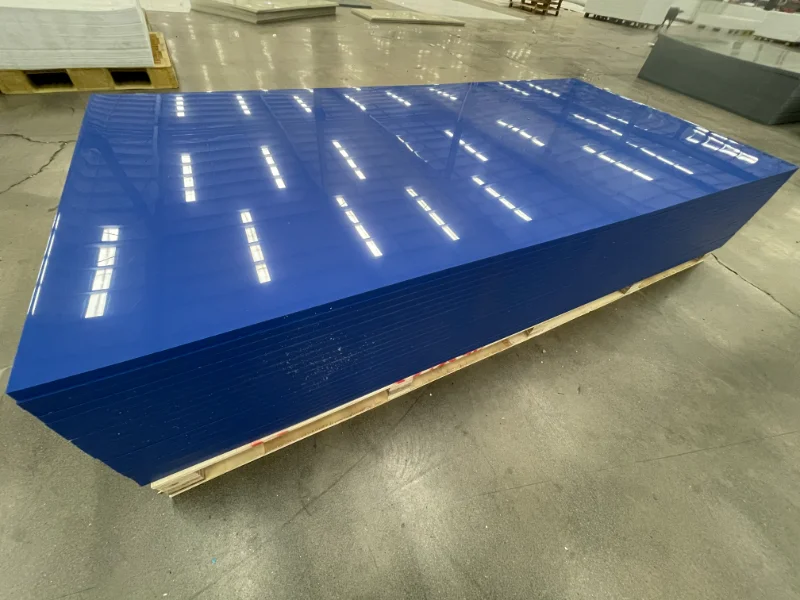

Introduction to FRPP Board

FRPP (Fiber-Reinforced Polypropylene) board is a type of board made by reinforcing polypropylene (PP) with 20% fiberglass. This process enhances the mechanical properties of the material, significantly improving its strength, rigidity, and other characteristics. FRPP boards retain the excellent qualities of standard PP while offering superior features like high heat resistance, low-temperature impact resistance, corrosion resistance, and low shrinkage.

Key Features of FRPP Board

1. Mechanical Properties

- Enhanced Strength and Rigidity: FRPP boards exhibit much higher strength and rigidity than standard PP boards due to the reinforcement of fiberglass. This makes them highly durable under external forces such as pressure and tension, ensuring that they don’t deform or break easily.

- Low Shrinkage: One of the standout features of FRPP boards is their low shrinkage rate during processing and usage. This property ensures dimensional stability, making it ideal for precision applications where high accuracy is required, such as in the manufacture of parts for precision instruments.

2. Physical Properties

- Excellent Heat Resistance: FRPP boards perform well in high-temperature environments, making them suitable for use in industrial equipment that needs to withstand elevated temperatures.

- Superior Low-Temperature Impact Resistance: Even in low-temperature settings, FRPP boards are resistant to cracking or breaking when impacted, ensuring their reliability in colder work environments. This makes them ideal for outdoor equipment in freezing regions.

3. Chemical Properties

- Corrosion and Arc Resistance: The boards have strong corrosion resistance, making them ideal for use in environments with exposure to various chemicals. Their arc resistance also makes them suitable for electrical applications where arc formation might occur.

- High Chemical Stability: FRPP boards are inert to most acids, bases, salts, and oxidizing agents. They offer stable performance in complex chemical environments, ensuring long-term durability.

Applications of FRPP Board

FRPP boards are used in numerous industries due to their unique properties, including:

1. Chemical Industry

In the chemical industry, FRPP boards are used for manufacturing components such as reaction vessel linings, pipelines, and valves. Their ability to withstand chemical corrosion ensures the longevity and efficiency of equipment.

2. Chlor-alkali Industry

The chlor-alkali process involves highly corrosive chemicals, and FRPP boards are used in the construction of storage containers, transport pipes, and other facilities to prevent corrosion and enhance equipment life.

3. Petroleum Industry

FRPP boards are essential in the petroleum industry, where they are used for oil well pipeline linings, oil storage tank liners, and other protective layers. Their durability helps meet the specific needs of petroleum extraction, refining, and storage.

4. Dye Industry

FRPP boards are used in the dye industry for equipment parts such as dyeing tank casings and dye transport pipes. They can withstand chemical corrosion from dyes and maintain their integrity at high temperatures.

5. Pesticide Industry

In pesticide production, storage, and transportation, FRPP boards prevent corrosion and help maintain the sealing integrity of equipment. Their chemical stability is particularly useful in dealing with harsh chemicals.

6. Food and Pharmaceutical Industries

Due to their high chemical stability, non-toxic, and odorless nature, FRPP boards are used in food processing equipment and pharmaceutical production components. They are often used for food conveyors and pharmaceutical storage containers, meeting stringent hygiene standards.

7. Light Industry

FRPP boards are commonly used in light industries like packaging machinery and plastic product processing equipment. Their strength, rigidity, and chemical stability make them perfect for structural or protective components.

8. Metallurgical Industry

In metallurgy, FRPP boards are utilized in manufacturing corrosion-resistant parts for auxiliary equipment, such as protective plates for metallurgical furnaces and inner linings for metal solution transport pipes.

9. Wastewater Treatment Industry

FRPP boards are essential in wastewater treatment facilities. They are used to construct parts such as liners for sewage tanks and pipes, ensuring durability against chemical and microbial corrosion.

Conclusion

FRPP boards offer a range of benefits that make them ideal for industries that require materials with high strength, heat resistance, chemical stability, and corrosion resistance. From chemical and petroleum industries to food and pharmaceutical sectors, FRPP boards prove to be indispensable for ensuring the durability and efficiency of equipment in harsh environments.