In today's rapidly developing construction industry, various large machinery equipment play a crucial role. Among them, the stability and reliability of construction machinery outriggers are vital, directly impacting the safety and efficiency of the entire operation. Recently, a revolutionary new outrigger pad made of advanced materials, specifically ultra-high molecular weight polyethylene (UHMW-PE), has made a stunning debut, bringing transformative changes to the industry.

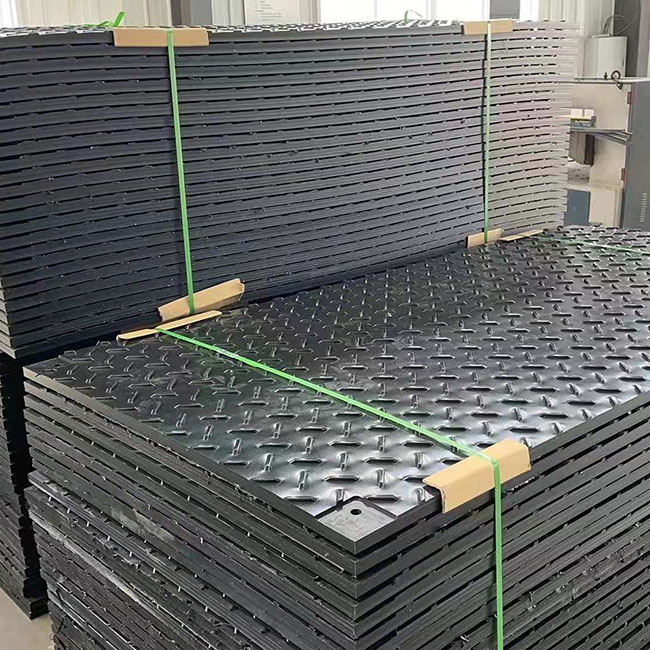

This outrigger pad uses ultra-high molecular weight polyethylene or high-density polyethylene as the primary material. These two special high polymer materials provide the pad with exceptional performance advantages. The pad features outstanding wear resistance, meaning that even in long-term, high-intensity usage environments, its surface is less prone to wear marks. Whether on rough, uneven construction site floors or in frequently moving and rubbing operational scenarios, the pad remains in excellent condition, significantly extending its service life, reducing the frequency of replacements due to wear, and lowering maintenance costs for the equipment.

Ultra-high Molecular Weight Polyethylene Outrigger Pad

Corrosion resistance is another standout feature of the ultra-high molecular weight polyethylene outrigger pad. In construction environments, various acidic and alkaline substances, corrosive liquids, and harsh weather conditions are often present, which can quickly damage outrigger pads made from ordinary materials. However, this new product, with its excellent corrosion resistance, can withstand such harsh environments, ensuring its structural integrity and providing continuous, stable support for construction machinery. For instance, in construction projects near chemical industrial parks, traditional pads may corrode and fail rapidly, while this new material outrigger pad can withstand such challenges, demonstrating superior adaptability.

In practical applications, the ultra-high molecular weight polyethylene outrigger pad is placed beneath the outriggers of construction machinery. Its main functions are:

- Support: It evenly distributes the weight of the machinery, ensuring smoother contact between the outrigger and the ground. This prevents excessive local pressure that could lead to ground subsidence or equipment instability.

- Prevention of Tire Slippage: Due to its unique material texture and surface design, the pad increases friction between the outrigger and the ground. Even in slippery conditions such as wet or oily surfaces, it firmly grips the ground, ensuring precise positioning and safe operation of the construction machinery during stationary tasks.

This new outrigger pad brings a significant upgrade to the construction equipment industry, offering enhanced durability, corrosion resistance, and operational stability.