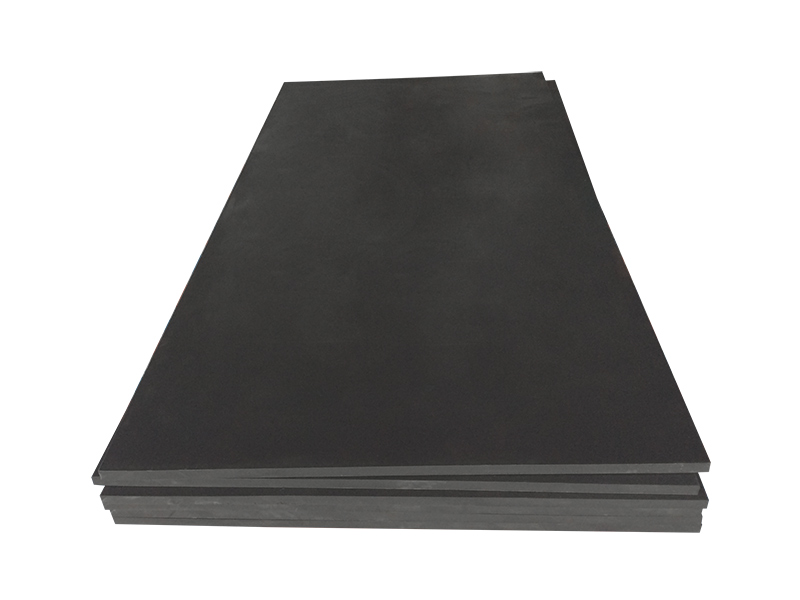

Mechanical Properties and Applications of UHMW-PE Sheets

Ultra-high molecular weight polyethylene (UHMW-PE) sheets are a high-performance thermoplastic material widely recognized for their outstanding mechanical properties, far surpassing conventional HDPE. With exceptional wear resistance, impact strength, low-temperature durability, and self-lubrication, UHMW-PE sheets have become essential in a wide range of industrial applications.

Key Mechanical Properties of UHMW-PE Sheets

1. Resistencia excepcional al impacto

UHMW-PE demonstrates extremely high impact strength, making it nearly unbreakable under sudden stress. In notched Izod impact tests, UHMW-PE typically shows "no break" results, indicating superior toughness in harsh environments.

2. Excelente resistencia al desgaste

With a very low wear rate (approx. 20 mm using MPC method), UHMW-PE outperforms most metals and traditional plastics in abrasive applications. This makes it ideal for lining chutes, hoppers, and other high-wear components.

3. Low Friction and Self-Lubrication

The coefficient of friction of UHMW-PE ranges from 0.07 to 0.11, providing smooth operation and minimizing the need for external lubricants. This reduces maintenance requirements and improves system longevity.

4. Excelente resistencia química

UHMW-PE resists corrosion from most acids, alkalis, salts, and organic solvents, making it suitable for chemical tanks, pipe linings, and protective barriers in corrosive environments.

5. Superior Low-Temperature Performance

UHMW-PE maintains its mechanical integrity even at temperatures as low as -269°C, making it suitable for cryogenic equipment and cold-chain logistics components.

6. Anti-Fatigue and Vibration Damping

Its high molecular weight structure allows it to withstand repetitive stress without fatigue, while also offering excellent noise and vibration damping properties.

7. Radiation Resistance

UHMW-PE is also resistant to radiation, making it suitable for applications in nuclear medicine, radiology, and other radiation-exposed environments.

Typical Properties (Molecular Weight ~2 million)

- Densidad: 0.935 g/cm³

- Service Temperature: -269°C to +110°C

- Tensile Strength: 40 MPa

- Elongation at Break: 350%

- Flexural Modulus: 600 MPa

For more detailed technical data and product options, visit Zhihong Plastic’s PE Sheet Category.

Industrial Applications of UHMW-PE Sheets

Thanks to its mechanical excellence, UHMW-PE is replacing traditional materials like carbon steel, stainless steel, and bronze in demanding industrial sectors:

1. Textile and Paper Machinery

Used for components such as shuttle rods, gears, connectors, and buffer blocks. In the paper industry, UHMW-PE serves in scraper blades, water removal components, sealing shafts, and filter plates.

2. Food Processing and Packaging

Due to its FDA-compliant, non-toxic, and self-lubricating nature, it is ideal for sliding parts, guide rails, and cutting surfaces in food-grade machinery.

3. Chemical and Wastewater Treatment

UHMW-PE is ideal for pump components, valve seats, lining materials for tanks and pipes, and scrapers in sedimentation tanks, ensuring long-term chemical resistance and cleanliness.

4. Mining and Bulk Material Handling

Commonly used for lining truck beds, chutes, and hoppers to reduce material adhesion and wear. It improves efficiency and extends the service life of mining and conveying equipment.

5. Medical and Nuclear Applications

Its radiation resistance and biocompatibility make it suitable for prosthetics, surgical components, and shielding in radiation-intensive environments.

Final Thoughts

UHMW-PE sheets offer a perfect combination of durability, performance, and cost-efficiency. With growing demand in sectors such as textiles, chemicals, food, and mining, selecting a trusted supplier is crucial.

Explore customized UHMW-PE sheet solutions from Plástico Zhihong—a manufacturer known for reliable quality and tailored engineering plastic products. For a complete list of available UHMW-PE and HDPE products, browse the PE product catalog here.