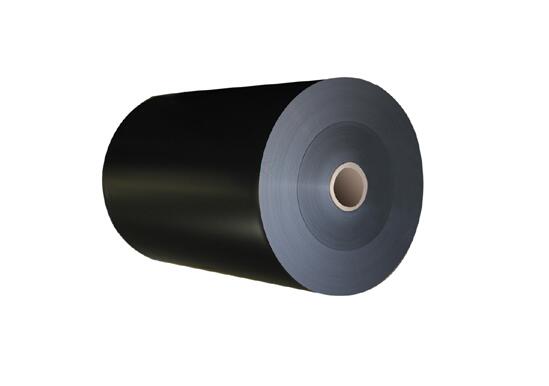

PE Thermoforming Roll Material

Densidad: 0.93g/cm³

Description:

This PE thermoforming roll material is ideal for frozen food packaging trays and microwaveable containers. It is of high quality, free from recycled materials and fillers. The material is easy to thermoform, offers high clarity, and ensures food-grade safety.

Propiedades físicas:

Polyethylene (PE) is a polymer derived from the polymerization of ethylene, with over 60 years of development history. It is the most widely produced plastic among the five major general-purpose resins worldwide.

Based on polymerization methods, molecular weight, and chain structure, polyethylene is categorized into:

- High Density Polyethylene (HDPE): Also known as low-pressure polyethylene, HDPE has superior heat resistance, oil resistance, vapor permeability resistance, and environmental stress crack resistance compared to LDPE and LLDPE. It also features excellent electrical insulation, impact resistance, and cold resistance. It is widely used in blow molding and injection molding.

- Low Density Polyethylene (LDPE): Also known as high-pressure polyethylene, LDPE is softer and more flexible due to its lower density. Common applications include plastic bags and agricultural films.

- Linear Low Density Polyethylene (LLDPE): A copolymer of ethylene and small amounts of higher α-olefins polymerized in the presence of a catalyst. It has a similar appearance to LDPE but with better surface gloss, low-temperature toughness, high modulus, bending resistance, and stress cracking resistance. It has largely replaced LDPE in most applications.

Polyethylene can be processed using extrusion, injection molding, blow molding, rotational molding, and melt spinning. It is widely used in industrial, agricultural, and daily packaging applications. In China, film products are the largest consumer of polyethylene, using approximately 77% of LDPE and 18% of HDPE. Other significant applications include injection-molded goods, wires and cables, and hollow containers.

Thermal Properties:

Polyethylene is a typical thermoplastic, appearing as a white, odorless, tasteless, and combustible powder. Processed PE resins are typically waxy granules in an off-white color. Their molecular weight ranges from 10,000 to over 1,000,000. Ultra-high molecular weight polyethylene (UHMWPE) exceeds 1,000,000 in molecular weight, offering excellent mechanical properties, although higher molecular weights also increase processing difficulty. The melting point is around 110–130°C. It maintains good mechanical strength even at −60°C, with a usable temperature range between 80–110°C.

Chemical Stability:

Polyethylene has excellent chemical resistance at room temperature. It withstands dilute nitric acid, dilute sulfuric acid, and all concentrations of hydrochloric acid, hydrofluoric acid, phosphoric acid, formic acid, acetic acid, ammonia, amines, hydrogen peroxide, sodium hydroxide, and potassium hydroxide. However, it is not resistant to strong oxidative corrosion, such as fuming sulfuric acid, concentrated nitric acid, and mixtures of chromic acid and sulfuric acid. These substances can corrode polyethylene slowly at room temperature and rapidly at 90–100°C.

When exposed to atmosphere, sunlight, and oxygen, polyethylene undergoes aging, discoloration, cracking, embrittlement, and chalking, losing its mechanical integrity. During processing, oxidation may cause melt viscosity reduction, discoloration, and streaks. Antioxidants or UV stabilizers should be considered to mitigate these effects. Given its recyclability and ease of processing, PE has high reuse value.

Electrical Properties:

Due to its non-polar nature, polyethylene features low dielectric loss and high dielectric strength. It serves as an excellent material for radio-frequency insulation and high-voltage insulation applications.

Product Range:

We specialize in the production of over a dozen product series, including:

- PS sheets

- Láminas de PP

- Láminas de PE

- PET sheets

- PET|PP food-grade sheets

- Láminas de HDPE and rolls

- PP sheets and rolls

- PS sheets and rolls

- ABS sheets and rolls

- ABS laminated TPU sheets and rolls

- Carrier tapes and cover tapes

- Reels and winding trays