Key Characteristics of PE and PP Plastic Products

PE Plastic Products

- Excellent Flexibility: PE plastic products are flexible like rubber, making them ideal for applications where products need to be bent or stretched. Even in low-temperature environments, PE remains resistant to cracking, making it suitable for applications such as piping systems that require easy installation and bending.

- High Chemical Resistance: PE has excellent resistance to a wide range of chemical substances including acids, bases, and salts. This high resistance makes it a strong choice for products exposed to chemical environments, such as chemical storage tanks and piping systems.

- Good Electrical Insulation: PE plastic products excel in electrical insulation, effectively preventing the passage of electrical currents. This makes PE a preferred material for electrical components like wire coatings and insulation parts for electrical equipment.

PP Plastic Products

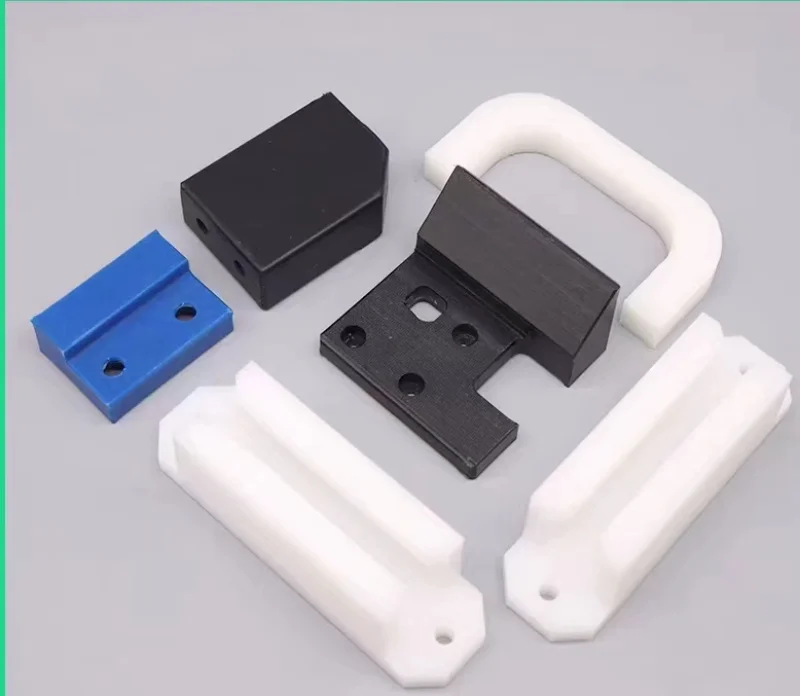

- High Strength and Rigidity: PP plastic products exhibit excellent strength and rigidity, making them ideal for applications where the material must withstand significant pressure or stress. This makes PP a great option for structural components in various industries.

- Outstanding Heat Resistance: PP performs well in high-temperature environments, maintaining its integrity and strength. As such, PP is commonly used for products exposed to heat, including kitchenware and automotive engine parts.

- Excellent Processability: PP is easy to mold and weld, which allows for efficient production of various shapes and sizes. This excellent processability makes PP an ideal material for mass production, enabling manufacturers to meet diverse design requirements.

Common Applications of PE and PP Plastic Products

PE Plastic Products

- Packaging Industry: PE is commonly used in the packaging of various products, such as plastic bags, bottles, and films. Its flexibility and chemical resistance help protect goods and extend shelf life.

- Agriculture: PE is widely used for irrigation pipes, agricultural films, and greenhouse components. It contributes to enhanced agricultural production through durable and reliable products.

- Environmental Protection: PE products such as landfill liners and wastewater treatment liners help prevent the leakage of pollutants, thus playing a crucial role in environmental protection efforts.

PP Plastic Products

- Automotive Industry: PP is extensively used for car parts, such as interior components (dashboard, seat shells) and engine peripherals (radiators, cooling fans), thanks to its high strength and heat resistance.

- Home Goods: PP is commonly used for manufacturing household items like furniture, utensils, and storage containers. Its high strength, ease of cleaning, and low cost make it a popular choice among consumers.

- Electronics and Electrical Industry: PP is used for creating electrical device casings and internal structural components, where electrical insulation is essential, and the material’s excellent processability enables a wide range of designs.

Conclusion

PE and PP plastic products offer versatile solutions across various industries due to their excellent material properties such as flexibility, chemical resistance, high strength, and heat resistance. Whether for packaging, agriculture, automotive, or electrical applications, these materials continue to be essential in modern manufacturing processes, offering high performance at cost-effective prices.