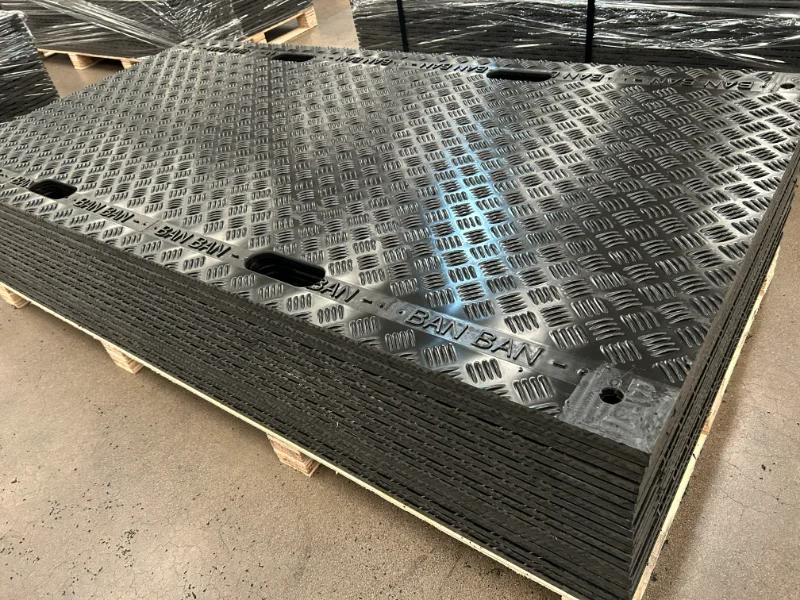

HDPE anti-slip road mats (also called ground protection panels / temporary access mats) create a stable driving and working surface on soft ground, sand, mud or grass. They help contractors, utilities and event organizers reduce rutting, protect finished surfaces, and keep equipment moving safely.

- High traction surface – anti-slip texture helps tires and tracks maintain grip in wet or muddy conditions.

- Load spreading – distributes point loads to reduce sinkage and ground damage (selection depends on thickness and subgrade).

- Lightweight & reusable – easier handling than steel plates; suitable for repeated projects.

- Weather & chemical resistance – HDPE performs in rain/snow and resists many common chemicals and oils.

- Custom fabrication – cut-to-size, drilled holes, logo marking, connection holes/slots on request.

Send your application details (vehicle type, ground condition, panel size, thickness and quantity) to get a matched specification and factory quote.

Key Specifications

| Item | Options / Range |

|---|---|

| Material | HDPE (UV-stabilized option available) |

| Surface | Anti-slip texture (single-side or double-side, by request) |

| Thickness | Common: 10–25 mm (custom available) |

| Panel size | Common: 1200×2400 mm / 1000×2000 mm (custom available) |

| Colors | Black, green, yellow, orange (custom by quantity) |

| Connection | Optional: interlocking edges / connection holes / straps |

| Processing | CNC cutting, drilling, chamfering, marking |

| Packing | Film protection + pallet/crate for export |

Product Features & Advantages

- Anti-slip walking & driving surface for safer access around equipment and work zones.

- Impact & wear resistance for repeated use on construction sites and temporary roads.

- Low water absorption to reduce swelling and maintain stable dimensions.

- Easy cleaning – mud and debris wash off; suitable for rental fleets.

- OEM support – label/marking, packaging and documentation for distributors.

Typical Applications

- Temporary access roads for construction machinery (excavators, cranes, trucks).

- Utilities & maintenance: power, telecom, pipeline and municipal works.

- Outdoor events: heavy foot traffic protection on lawns and parks.

- Oil & gas, wind farm and solar site access (temporary routes).

- Work platforms around generators, pumps and storage areas.

Customization Options

- Panel length/width/thickness according to load requirement and handling method.

- Surface texture pattern (anti-slip), single/double side.

- Edge treatment: rounded corners, chamfering, beveled edges.

- Connection features: holes, slots, interlocks, rope handles.

- Color match and OEM logo marking (MOQ applies).

Quality Control & Service

- Incoming material verification and batch traceability.

- Thickness, length/width and flatness inspection with records (available on request).

- Surface inspection for bubbles, contamination and texture consistency.

- Pre-shipment photos and packing confirmation.

- Export support: packing list, invoice, HS code assistance.

Ordering Information

- Tell us your use case: vehicle type (wheeled/tracked), max axle load, turning/braking behavior.

- Ground condition: mud/sand/grass/gravel; expected moisture and slope.

- Panel requirement: preferred size, thickness, surface texture, connection method.

- Quantity & destination: order quantity, port/city, delivery time requirement.

- We reply with: recommended spec, MOQ, lead time, packing and best factory price.

FAQ

What thickness should I choose for my equipment?

Selection depends on subgrade and load. Share your vehicle type and ground condition; we will recommend a suitable thickness and panel size.

Are the mats suitable for tracked machines?

Yes. For tracked equipment, we typically recommend thicker panels and appropriate texture/edge treatment to reduce movement.

Do you offer UV-resistant outdoor grade panels?

Yes. UV-stabilized material can be supplied for long-term outdoor exposure.

Can I get interlocking or connection holes?

Yes. We can add holes/slots or interlocking edges based on your installation method.

Do the mats float on water?

HDPE has low density and can float, but field behavior depends on panel design and attachments.

Can you provide cut-to-size and drilling?

Yes. CNC cutting, drilling and chamfering are available. Send your drawing or requirements.

What colors are available?

Common colors include black and green; other colors can be customized by quantity.

How do you pack for export?

Film protection plus pallets or crates, with export markings if required.

What is the typical lead time?

It depends on size, thickness and quantity. We will confirm lead time with your spec and order volume.

Can you support distributors with OEM branding?

Yes. We can provide OEM labeling/marking and stable batch supply for distribution projects.