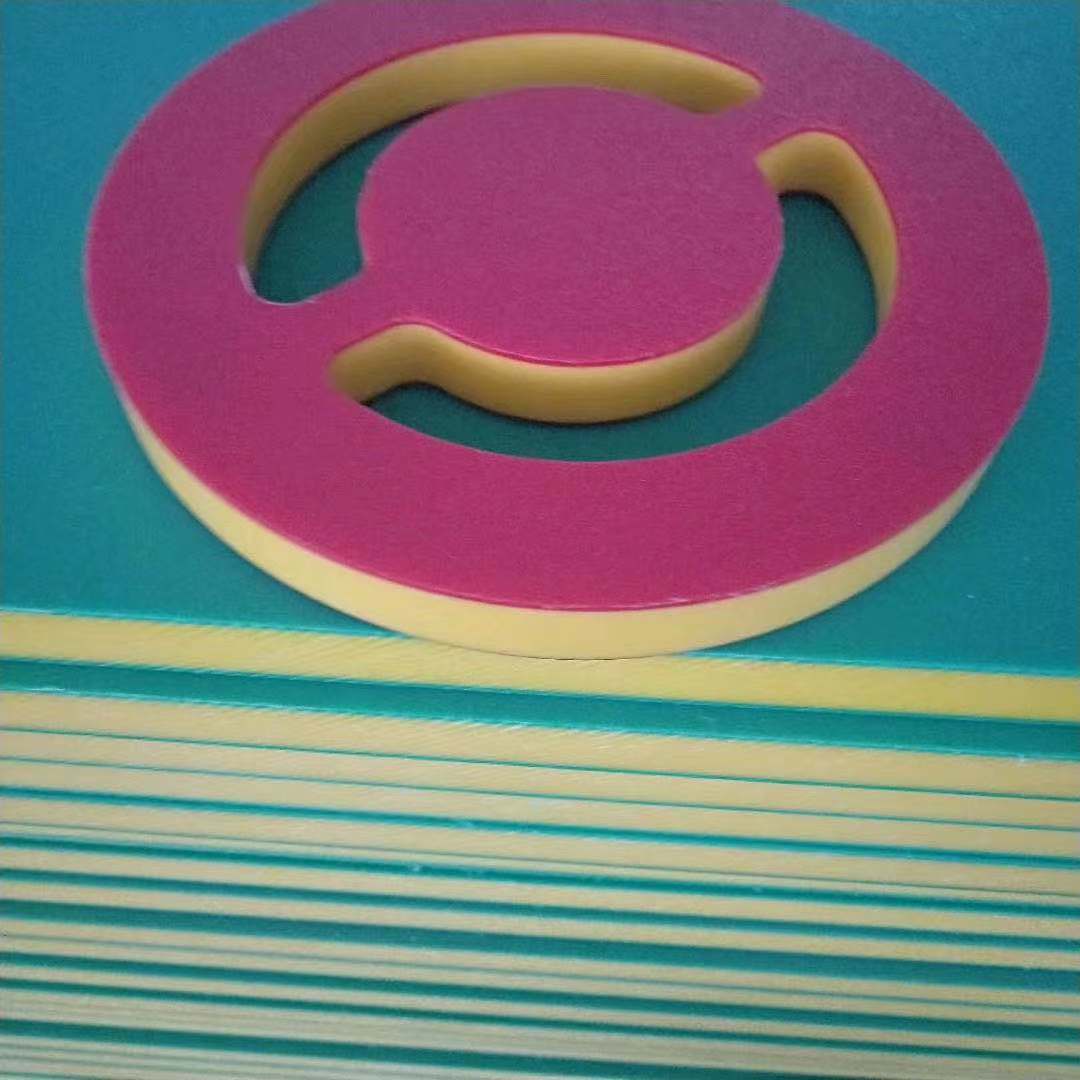

HDPE Two-Color Sheets are solid, engravable polyethylene boards engineered for signage, marine, outdoor facilities and recreational equipment. Manufactured using a multi-layer co-extrusion (multi-fusion) process, each sheet combines a thin color cap with a contrasting core, allowing clean engraving without paint, printing or lamination.

Both surfaces feature a matte finish to reduce glare and visible scratches, making the material suitable for indoor and outdoor use where appearance, durability and low maintenance are required.

Typical Applications:

- Signage & Wayfinding: engraved signs, safety labels, information boards and nameplates

- Marine & Waterfront: dock signs, boat components and moisture-exposed panels

- Playgrounds & Recreation: durable, impact-resistant panels for public-use equipment

- Interior & Exterior Panels: decorative boards and architectural elements requiring color contrast

These applications benefit from the material’s color-through construction, strong impact resistance and resistance to water, humidity and daily wear.

Performance & Durability:

HDPE Two-Color Sheets are formulated for outdoor stability, with good resistance to UV exposure, moisture and temperature changes. Unlike painted or laminated boards, the color layers will not peel, rust or delaminate, ensuring consistent appearance throughout service life.

The base material is a high-impact polyethylene that withstands abuse, repeated handling and impact better than traditional signage substrates such as PVC foam or acrylic in demanding environments.

Fabrication & Engraving:

The sheets can be cut, routed, drilled and engraved using standard woodworking or CNC equipment. The cap layer thickness (approx. 0.050 inch) allows precise engraving with sharp contrast, eliminating the need for secondary finishing such as painting or polishing.

HDPE Two-Color vs PVC / Acrylic for Signage

If you are choosing a substrate for engraved signs, the table below highlights the practical differences that affect service life, appearance and maintenance cost.

| Comparison Item | HDPE Two-Color Sheet | PVC Sheet (Foam/Expanded) | Acrylic Sheet |

|---|---|---|---|

| Engraving Contrast | High (cap reveals core color) | Medium (often needs paint/film for best contrast) | Medium–High (but edges can chip) |

| Outdoor Durability | Good (UV-stabilized option available) | Fair (can age, warp, or become brittle) | Fair–Good (UV stable but can crack under impact) |

| Impact Resistance | Excellent (tough, abuse-resistant) | Medium (can dent or crack) | Low–Medium (brittle, prone to cracking) |

| Moisture / Water Resistance | Excellent (no rust, no delamination) | Good | Excellent |

| Scratch Visibility | Lower with matte/textured surface | Medium (surface can mark) | Higher (scratches show easily) |

| Machining & CNC | Easy (woodworking tools compatible) | Easy (but dust/edge quality varies) | More demanding (risk of cracking/chipping) |

| Maintenance | Low (no repainting; color-through) | Medium (surface aging/printing wear) | Medium (scratch/crack risk) |

| Best Use Cases | Outdoor/public signage, marine, playgrounds, industrial labels | Short-to-mid term indoor signage, displays | Premium indoor signs, light boxes, decorative panels |

Standard color combinations are coordinated at the production stage, helping reduce post-processing cost and improving consistency for repeat orders.

Hygiene & Surface Protection:

Optional antibacterial formulations help inhibit the growth of bacteria, algae and fungi on the surface, reducing stains and odors in public-use or humid environments.