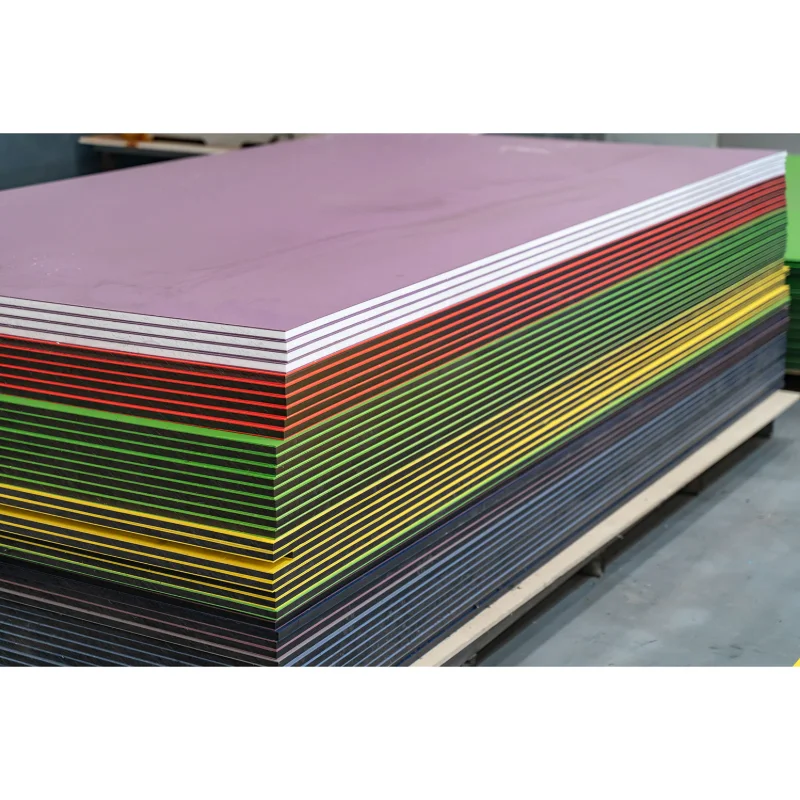

HDPE two-color sheets are double-layer plastic boards designed to reveal a contrasting core color after engraving or machining. They are widely used for signage, labels, nameplates, routing panels and durable industrial identification—especially where moisture, chemicals and outdoor weather are concerns.

- Clean engraving contrast – top layer removes neatly to show the core color.

- Outdoor durability – UV-stabilized options for long-term exposure.

- Chemical & moisture resistance – suitable for workshops, plants and wet environments.

- Easy processing – CNC routing, laser engraving (process depends on thickness), drilling and cutting.

- Factory customization – thickness, sheet size, color pairings and surface finish.

Send your color combination, thickness, sheet size/drawing and quantity to receive MOQ, lead time and a factory quotation.

Key Specifications

| Item | Options / Range |

|---|---|

| Material | HDPE two-layer (two-color) |

| Structure | Surface color + core color (engraving contrast) |

| Thickness | Common: 0.8–6 mm (custom available) |

| Sheet size | Common: 1220×2440 mm (custom available) |

| Surface finish | Matte / smooth / textured (by request) |

| Color pairs | Black/white, white/black, red/white, blue/white, yellow/black (custom by quantity) |

| Processing | CNC routing, cutting, drilling, corner rounding; custom shapes |

| Packing | Protective film + carton/pallet; export marking |

Product Features & Advantages

- Stable contrast for readable text and graphics after engraving.

- Low water absorption helps maintain dimensional stability.

- Electrical insulation suitable for industrial labeling and panels.

- Non-toxic & odorless material option for general signage use.

- Consistent batches for project continuity and distributor supply.

Typical Applications

- Engraved signage: indoor/outdoor nameplates, room numbers, directional signs.

- Equipment labels and safety tags for factories and utilities.

- Control panels, instrument faceplates and routing templates.

- Industrial identification boards in wet, chemical or dusty environments.

- Custom CNC-machined plastic parts where color coding is needed.

Customization Options

- Color pairing and sheet thickness per application and engraving depth.

- Protective film on one or both sides.

- Cut-to-size, corner rounding, drilling, die-cut shapes.

- OEM packing, labels and pallet configuration for distributors.

Quality Control & Service

- Color consistency check between surface and core.

- Thickness and sheet size measurement with documented tolerances.

- Surface inspection for scratches, bubbles and contamination.

- Packing inspection and pre-shipment photos.

Ordering Information

- Tell us your process: CNC engraving, routing, laser (if applicable) and desired contrast.

- Specify: surface/core color, thickness, sheet size or drawing.

- Quantity: sheets or square meters; repeat order expectations.

- Destination: delivery city/port and required Incoterms.

- We reply with: MOQ, lead time, packing and factory price.

FAQ

What’s the difference between two-color HDPE and normal HDPE sheets?

Two-color sheets are double-layer boards. After engraving or machining the surface layer, the core color appears to create high-contrast text/graphics.

Can you customize the color combinations?

Yes. Provide your target surface/core colors and order quantity; we will confirm feasible pairings and MOQ.

Is it suitable for outdoor signs?

Yes. For outdoor use, we recommend UV-stabilized material and suitable thickness for rigidity.

What thickness is best for engraving?

It depends on engraving depth and rigidity needs. Tell us your artwork depth and application; we’ll recommend a practical thickness.

Can you supply sheets with protective film?

Yes. Film protection can be applied to reduce scratches during processing and transport.

Do you offer cut-to-size or CNC machining?

Yes. We can cut, drill and CNC machine according to your drawing for faster assembly.

Will the sheet crack in cold weather?

HDPE has good low-temperature toughness, but performance depends on thickness and installation. Share your environment and we’ll advise.

What tolerance can you control?

We can control thickness and dimensions within typical industrial tolerances; exact tolerance depends on thickness and size—request details when quoting.

How is the product packed for export?

Protective film plus carton and pallet/crate packing as required for export.

Can you support distributors and repeat projects?

Yes. We can provide stable batches, OEM packing and consistent supply for distribution and project orders.