Transparent PP sheets (polypropylene clear sheets) offer a practical balance of clarity, toughness and chemical resistance. They are commonly used for protective covers, packaging, partitions, visual panels and general fabrication where lightweight, moisture resistance and easy processing are needed.

- Good transparency – suitable for viewing windows and protective barriers.

- Lightweight – easier handling than glass or thick acrylic in many applications.

- Chemical & moisture resistance – performs well in humid areas and many industrial environments.

- Easy fabrication – cutting, drilling and thermoforming are available depending on thickness.

- Custom supply – thickness, sheet size, protective film and cut-to-size.

Send your required thickness, clarity level, sheet size/drawing and quantity for MOQ, lead time and factory pricing.

Key Specifications

| Item | Options / Range |

|---|---|

| Material | PP (transparent/clear grade) |

| Thickness | Common: 0.5–10 mm (custom available) |

| Sheet size | Common: 1220×2440 mm (custom available) |

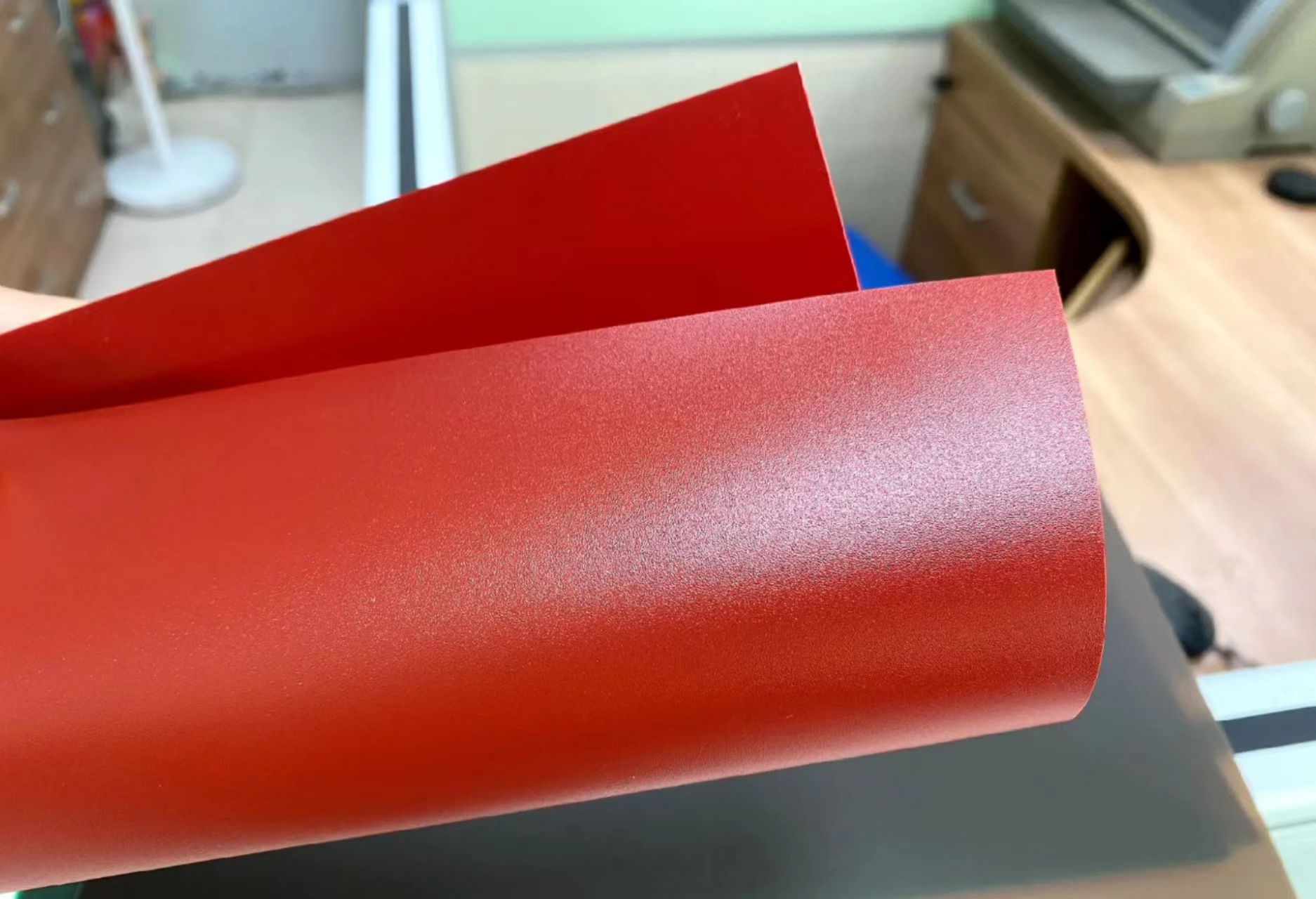

| Surface | Glossy / matte (by request) |

| Protective film | Single-side or double-side (recommended for transport/processing) |

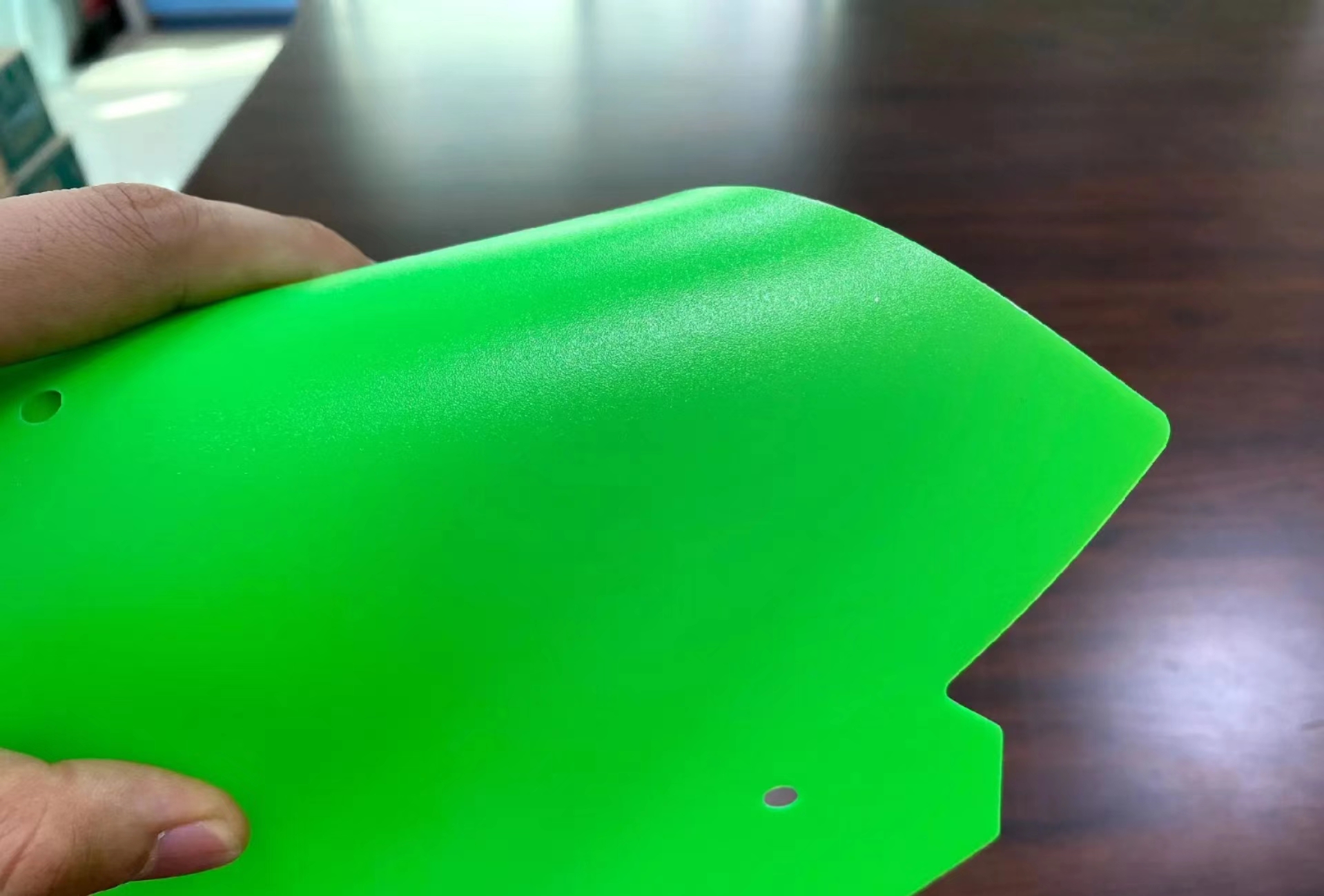

| Processing | Cut-to-size, drilling, die cutting; thermoforming (depending on grade) |

| Color | Clear (primary); translucent options by request |

| Packing | Film protection + carton/pallet for export |

Product Features & Advantages

- Moisture resistant – low water absorption compared with many materials.

- Impact resistance for general protective covers and barriers.

- Good fatigue resistance for repeated handling in packaging and partitions.

- Cost-effective option for large-area transparent panels.

- Stable batch supply for project and wholesale orders.

Typical Applications

- Protective shields, partitions and machine guards (application-dependent).

- Packaging: trays, covers and protective inserts (forming depends on thickness/grade).

- Viewing windows for equipment enclosures and inspection panels.

- Industrial covers, liners and general fabrication parts.

- Printed or laminated panels where lightweight transparency is required.

Customization Options

- Thickness and sheet size customization based on rigidity and processing needs.

- Protective film, edge finishing, corner rounding and drilled holes.

- Cut-to-size and shaped parts (die cut/CNC) for assembly lines.

- OEM packing and labeling for distributors.

Quality Control & Service

- Transparency/appearance inspection for haze, bubbles and scratches.

- Thickness and dimension checks with tolerances (on request).

- Protective film and packing inspection before shipment.

- Pre-shipment photos and export packing support.

Ordering Information

- Tell us the use: packaging/forming, protective cover, partition, printing, etc.

- Specify: thickness, sheet size or drawing, surface finish and film requirement.

- Quantity: sheets or square meters; repeat order plan if any.

- Destination: city/port and required delivery time.

- We reply with: matched grade, MOQ, lead time, packing and factory price.

FAQ

Is PP clearer than PVC or PET?

Clarity depends on the grade and thickness. Tell us your clarity requirement and we’ll recommend a suitable PP sheet option.

Can transparent PP sheets be thermoformed?

Many PP grades can be thermoformed, but results depend on thickness and process settings. Share your forming method and we’ll advise.

Do you provide protective film?

Yes. Single-side or double-side film is available to reduce scratches during transport and processing.

What thickness should I choose for a protective shield?

It depends on span, rigidity requirement and installation. Share your size and use scenario for a recommendation.

Is PP resistant to chemicals?

PP has good resistance to many chemicals, but compatibility depends on media and temperature—please share details.

Can you cut to size and drill holes?

Yes. We provide cutting, drilling and edge finishing to match your assembly.

Will PP sheets turn yellow outdoors?

Long-term UV exposure can affect plastics. For outdoor use, consider UV-stabilized material or protective design.

What is the difference between clear and translucent PP?

Clear focuses on transparency; translucent diffuses light. We can supply both depending on your needs.

How do you pack for export?

Protective film plus carton and pallet/crate packing as required.

Do you support wholesale/distributor supply?

Yes. We support stable batch supply, OEM packing and repeat orders.