HDPE 100 sheets are high-density polyethylene boards commonly selected for chemical resistance, toughness and fabrication stability. They are used for tank fabrication, linings, machining blocks and wear applications where reliable performance is required.

- Chemical resistance – suitable for many acids/alkalis/salts (verify media and temperature).

- High toughness – impact resistance helps in heavy-duty industrial use.

- Low water absorption – stable size in wet environments.

- Weldable & machinable – suitable for fabrication and CNC parts.

- Custom supply – thickness, sheet size, color and processing options.

Send your application, chemical media, thickness/size and quantity for MOQ, lead time and factory price.

Key Specifications

| Item | Options / Range |

|---|---|

| Material | HDPE 100 grade (application-dependent) |

| Thickness | Common: 2–100 mm (custom available) |

| Sheet size | Common: 1220×2440 mm / 1500×3000 mm (custom available) |

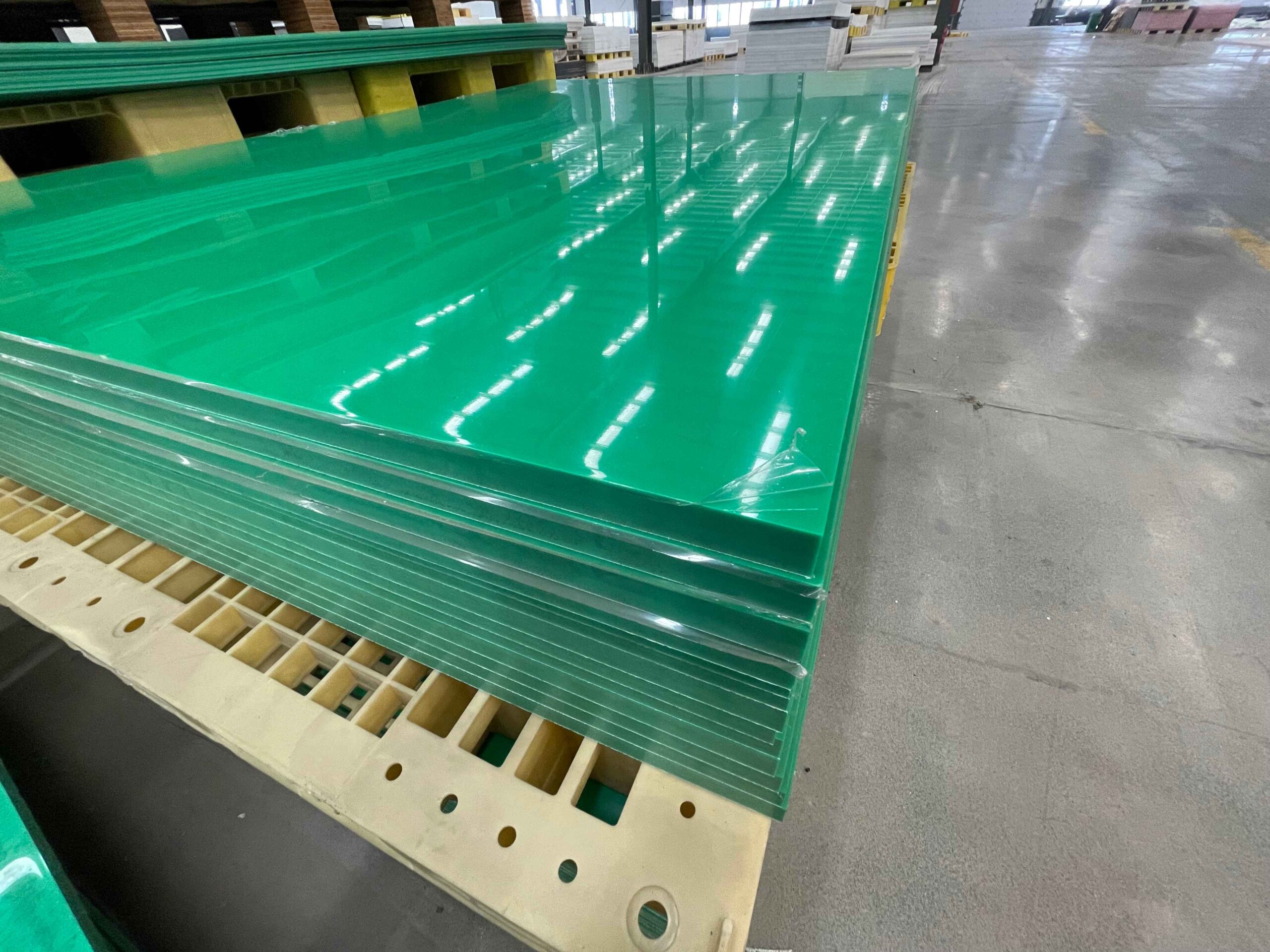

| Surface | Smooth / textured (by request) |

| Color | Black, natural, grey (custom by quantity) |

| Processing | Cut-to-size, CNC machining, drilling, chamfering |

| Fabrication | Plastic welding for tanks/linings (design-dependent) |

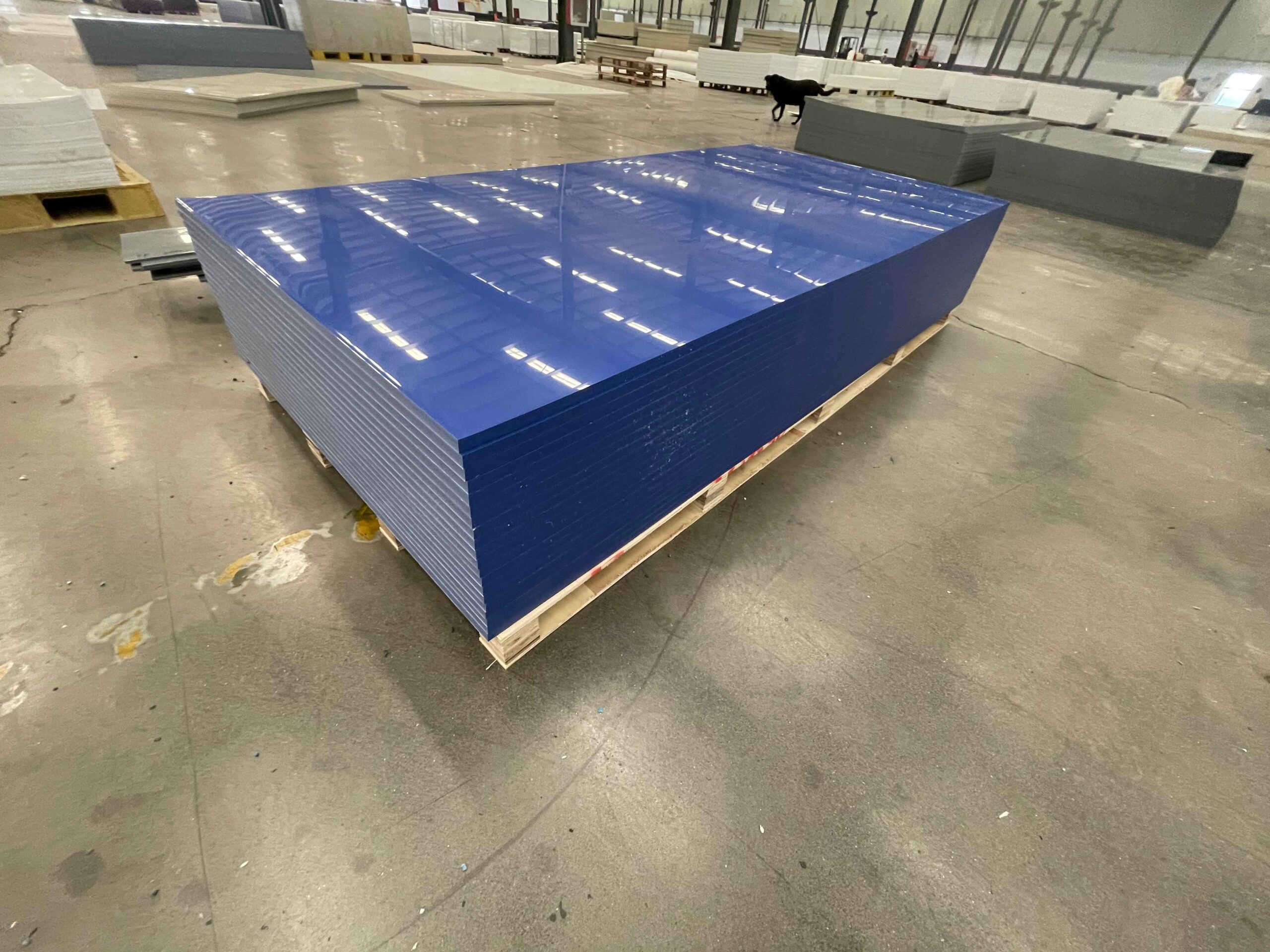

| Packing | Film protection + pallet/crate for export |

Product Features & Advantages

- Excellent toughness for heavy-duty handling and impact.

- Good wear performance for sliding contacts and liners (application-dependent).

- Corrosion-resistant alternative to metal in many chemical environments.

- Lightweight compared with metals for easier installation.

- Cost-effective lifecycle due to reduced maintenance in corrosive service.

Typical Applications

- Chemical storage tanks, welded fabrication panels and covers.

- Tank linings and splash guards for water treatment and chemical plants.

- Machined blocks, spacers, wear pads and support components.

- Pickling/plating auxiliary parts where chemical resistance is needed (confirm compatibility).

- Industrial protection boards and heavy-duty panels.

Customization Options

- Thickness and sheet size based on your fabrication design and rigidity needs.

- Cut-to-size, drilled holes and CNC-machined parts from drawings.

- Color, surface texture and protective film options.

- OEM packing/labels for distribution and project supply.

Quality Control & Service

- Thickness and dimension checks with tolerances (on request).

- Surface inspection for inclusions and defects.

- Batch traceability for repeat projects.

- Pre-shipment inspection and packing confirmation.

Ordering Information

- Media: chemical name, concentration and operating temperature.

- Specification: thickness, sheet size/drawing, quantity and color.

- Processing: cut-to-size / machining / welding fabrication needs.

- Delivery: destination port/city, Incoterms and lead time.

- We reply with: recommended grade, MOQ, lead time, packing and factory quote.

FAQ

What does HDPE 100 mean?

Naming can vary by market and application. Tell us your required performance and use scenario; we will confirm a suitable material grade.

Is HDPE 100 suitable for chemical tanks?

HDPE is widely used for chemical tanks, but suitability depends on media and temperature. Share your media list to confirm compatibility.

Can HDPE sheets be welded?

Yes. HDPE can be plastic welded for tank fabrication and linings; parameters depend on thickness and design.

What thickness should I choose?

It depends on span, load and design. Send drawings or dimensions for a recommendation.

Do you provide cut-to-size and machining?

Yes. We can cut and CNC machine to your drawing for faster assembly.

Is HDPE resistant to UV outdoors?

Standard HDPE can degrade under UV over time. For outdoor use, we recommend UV-stabilized material or black UV grade.

What sheet sizes do you supply?

Common sizes include 1220×2440 mm and 1500×3000 mm; custom sizes are available.

How do you pack for export?

Film protection plus pallet/crate packing for safe international shipping.

Can you supply for projects and distributors?

Yes. We support stable batches, OEM packing and repeat orders.

What information do you need to quote?

Thickness, sheet size, quantity, color, destination, and your application/chemical media if relevant.