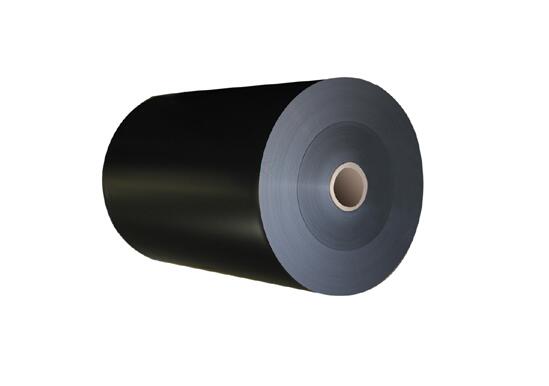

HDPE sheet and board is a tough, chemically resistant engineering plastic used for fabrication, lining, machining and general industrial protection. It combines high rigidity, impact strength and very low moisture absorption, making it reliable for wet, corrosive, or heavy-use environments where metal or wood panels fail prematurely.

Our HDPE boards feature a uniform surface and stable thickness, suitable for CNC cutting, drilling, routing, welding, and thermoforming. For project buyers, this means faster fabrication, less scrap, and more consistent assembly across batches.

Why HDPE for Industrial Projects

- Chemical resistance: performs well against many acids, alkalis, salts and cleaning agents

- Impact & wear performance: resists cracking and chipping in daily handling and repeated impacts

- Low moisture absorption: stable dimensions in wet areas, wash-down zones and outdoor humidity

- Easy fabrication: CNC machining, cutting, welding and forming-friendly

- Electrical insulation: suitable for non-conductive panels and protective parts

Key Specifications (Common Range)

Below is a practical specification range for sourcing and quotation. If your project has tighter tolerance or special performance targets, we can match the formulation and process accordingly.

- Density: 0.940–0.976 g/cm³

- Sheet thickness: 0.8–13 mm

- Roll thickness (HDPE): up to 8 mm

- Max width (HDPE/PP/PS): up to 2.3 m

- Max width (ABS): up to 1.9 m

- Cold-resistant grade: down to -30°C (optional)

- Surface: smooth / textured (by request)

- Color: natural / black / customized colors

Performance Notes for Buyers

- Temperature capability: suitable for general industrial use up to around 100°C in continuous service (application-dependent)

- Outdoor use: standard HDPE will age under UV; choose UV-stabilized grade for sunlight exposure

- Surface & printing: HDPE has low surface energy; printing/lamination may require surface treatment

- Scratch behavior: HDPE is tough but can scratch; textured surface helps hide marks in visible areas

Grades & Options We Can Supply

To match different industries and compliance needs, we offer multiple HDPE and engineering sheet grades. Tell us your working environment (chemicals, temperature, load, outdoor/indoor), and we will recommend a suitable option.

- UV & weather-resistant: for outdoor panels and exposed applications

- Flame-retardant: for equipment housing and specific safety requirements

- Anti-static / ESD: for electronics handling, cleanrooms, and packaging lines

- Conductive: for special discharge or shielding needs

- Cold-resistant: for low-temperature logistics and outdoor winter conditions

- Wear-resistant: for sliding surfaces, guides and protective liners

Typical Applications

HDPE boards are commonly selected when buyers need chemically stable, tough and easy-to-fabricate panels or parts.

- Industrial fabrication: machining plates, cutting/printing boards, jigs & fixtures, protective covers

- Tank & equipment protection: liners, splash guards, wear strips, corrosion-resistant panels

- Logistics & handling: turnover boxes, heavy-duty bins, reusable trays and separators

- Automotive & RV: interior panels, non-structural covers, storage compartments

- Cold-chain products: cooler shells, insulated container panels, low-temp handling parts

Zhihong Plastic – Engineering Sheet Capability

We manufacture and supply HDPE, ABS, TPU, TPV, TPEE, PP and HIPS sheets and rolls for industrial and packaging customers. For project orders, we can support stable batch supply and documentation-based QC.

- Production format: sheets, thick plates, rolls

- Quality control: thickness/tolerance checks, surface inspection, batch traceability (records available)

- Value-added services: cut-to-size, CNC machining (by request)

- Export packing: film protection, pallet/crate packing, export marking

Bulk & Project Supply

- Custom options: thickness, width, sheet size, color, textured/smooth surface, cut-to-size and CNC machining (by request)

- Quality: stable batches, dimensional checks and surface inspection (records available)

- Packing: film protection, pallet/crate packing, export marking

Get a Factory Quote

Send your material, thickness, sheet size / drawing, quantity and destination. We will reply with MOQ, lead time and a factory quotation.

FAQ – HDPE Sheets & Boards

1) What information do you need to quote quickly?

Please send thickness, sheet size (or drawing), quantity, required grade (standard/UV/FR/ESD), and destination port. We will confirm MOQ, lead time and factory pricing.

2) Can you produce large-width HDPE sheets for projects?

Yes. Standard production supports widths up to 2.3 m for HDPE/PP/PS. Share your target width and thickness to confirm feasibility and tolerance.

3) What thickness range do you supply?

HDPE sheets are available from 0.8–13 mm. HDPE rolls can be supplied up to 8 mm depending on the application and handling requirements.

4) Do you offer UV-stabilized HDPE for outdoor use?

Yes. For outdoor exposure we recommend UV-stabilized grades to slow down aging and discoloration. Tell us your service environment and expected lifespan target.

5) Can you supply anti-static (ESD) or conductive HDPE sheets?

Yes. We provide anti-static/ESD and conductive options for electronics handling, cleanrooms and packaging lines. Please specify your surface resistivity target if available.

6) Is HDPE suitable for chemical tanks or corrosive environments?

HDPE has strong resistance to many acids, alkalis and salts at room temperature, so it is widely used for liners, splash guards and protective panels. Share the chemical list and temperature range so we can confirm compatibility.

7) What surface options do you offer for visible panels?

We can supply smooth or textured surfaces. Textured finishes are often chosen to reduce visible scratches in high-contact applications.

8) Can you provide cut-to-size or CNC machining?

Yes. For project buyers we can support cut-to-size and CNC machining based on your drawing, helping reduce on-site processing time.

9) How do you control thickness tolerance and batch consistency?

We run dimensional checks and surface inspection with batch records available. For repeat orders, we prioritize stable formulation and process settings to keep performance consistent.

10) What packing method do you use for export shipments?

Standard export packing includes film protection plus pallet or crate packing with export markings. If your destination has special requirements, we can follow your packing instructions.