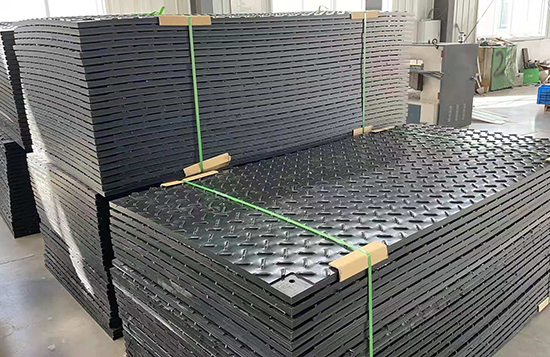

As a modern alternative to traditional concrete or asphalt, HDPE road mats (also known as polyethylene paving panels) have gained significant popularity in temporary and permanent road surface applications. These industrial-grade panels are designed to offer durability, lightweight handling, and environmental safety, making them an practical option for construction sites, event grounds, oil and gas fields, and more.

What Are HDPE Road Mats Made Of?

The core material of HDPE road mats is high-density polyethylene (HDPE) — a non-toxic, highly crystalline thermoplastic polymer. HDPE features:

- Excellent impact resistance

- Outstanding chemical and corrosion resistance

- Low water absorption

- High tensile strength

These properties make HDPE paving panels suitable for extreme environments, from wet and muddy conditions to dry, rugged terrains. Unlike concrete, HDPE panels do not crack under heavy loads and require minimal maintenance over time.

How to Install HDPE Road Panels

Proper installation is key to the long-term performance of polyethylene road panels. Here is a step-by-step guide:

- Site Assessment & Planning

Begin with a thorough site inspection and layout planning to determine the necessary panel coverage, traffic load, and terrain characteristics. - Surface Preparation

Clear debris, vegetation, and moisture from the ground. A level base improves panel contact and reduces movement during use. - Panel Placement

Lay the HDPE panels edge to edge, ensuring tight connections. Most panels come with overlapping joints or integrated connection systems for a secure fit. - Fastening & Stabilization

Use steel pins or interlocking connectors to secure the panels. Anti-slip surface textures further enhance safety during wet or uneven conditions. - Inspection & Maintenance

After installation, inspect for gaps or lifting corners. Periodic checks help maintain performance, especially under frequent vehicle loads.

Key Advantages of HDPE Road Mats

✔️ Lightweight & Portable

Compared to steel or concrete slabs, HDPE panels are easy to transport, handle, and install without heavy machinery.

✔️ High Load-Bearing Capacity

These mats support heavy-duty vehicles, including trucks, cranes, and military equipment — perfect for temporary access roads or ground protection.

✔️ Excellent Chemical & Weather Resistance

HDPE is immune to water, acids, and most solvents. This ensures long service life even in aggressive outdoor environments.

✔️ Environmentally Friendly

HDPE panels are 100% recyclable, non-polluting, and do not leach harmful substances into the soil — aligning with sustainable development goals.

✔️ Slip-Resistant Surface

The surface design offers enhanced traction, reducing slipping hazards in wet or uneven conditions — crucial for construction and industrial safety.

Technical Specifications

| Property | Value |

|---|---|

| Material | High-Density Polyethylene (HDPE) |

| Size (Standard Panel) | 2440mm × 1220mm × 15–20mm |

| Weight | Approx. 33–50kg per panel |

| Surface Finish | Anti-slip textured surface |

| Load Capacity | Up to 80 tons (depending on thickness) |

| Operating Temperature | -60°C to +80°C |

| Environmental Resistance | UV, moisture, corrosion, chemicals |

🔗 Learn more: Click here for full specs

Why Choose HDPE Road Mats from Zhihong Plastic?

Zhihong Plastic offers HDPE road mats with precision-engineered designs, high-grade raw materials, and custom manufacturing services. Whether you're in construction, logistics, or energy sectors, our road protection solutions ensure reliability, cost-efficiency, and safety.

Get a Free Quote Today

Thinking about improving ground access for your next project?

✅ Custom sizes & thicknesses available

✅ OEM & bulk supply options

✅ Fast delivery across international markets

👉 Contact Us Now or Request a Quote and discover how our HDPE road paving panels can transform your operations.

Bulk & Project Supply

- Custom options: thickness, size, color, cut-to-size and CNC machining (by request)

- Quality: stable batches, dimensional checks and surface inspection (records available)

- Packing: film protection, pallet/crate packing, export marking

Get a Factory Quote

Send your material, thickness, sheet size / drawing, quantity and destination. We will reply with MOQ, lead time and a factory quotation.