Marine-grade HDPE sheets are designed for harsh environments where saltwater exposure, UV sunlight and wet surfaces are daily conditions. They are widely used in aquaculture and marine projects for walkways, panels, fenders, covers and corrosion-resistant components.

- Saltwater & corrosion resistance – an alternative to metal in many marine structures.

- UV-stabilized options for long-term outdoor exposure on docks and farms.

- Low water absorption helps maintain stable dimensions in wet use.

- Anti-slip surface options to improve safety on walkways.

- Custom fabrication – cut-to-size, drilled holes, textured surfaces.

Send your project location (UV/salt), panel size, thickness, surface requirement and quantity for MOQ and factory pricing.

Key Specifications

| Item | Options / Range |

|---|---|

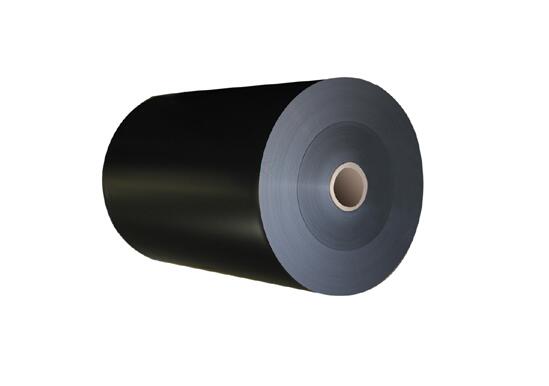

| Material | HDPE (marine / UV-stabilized option available) |

| Thickness | Common: 5–50 mm (custom available) |

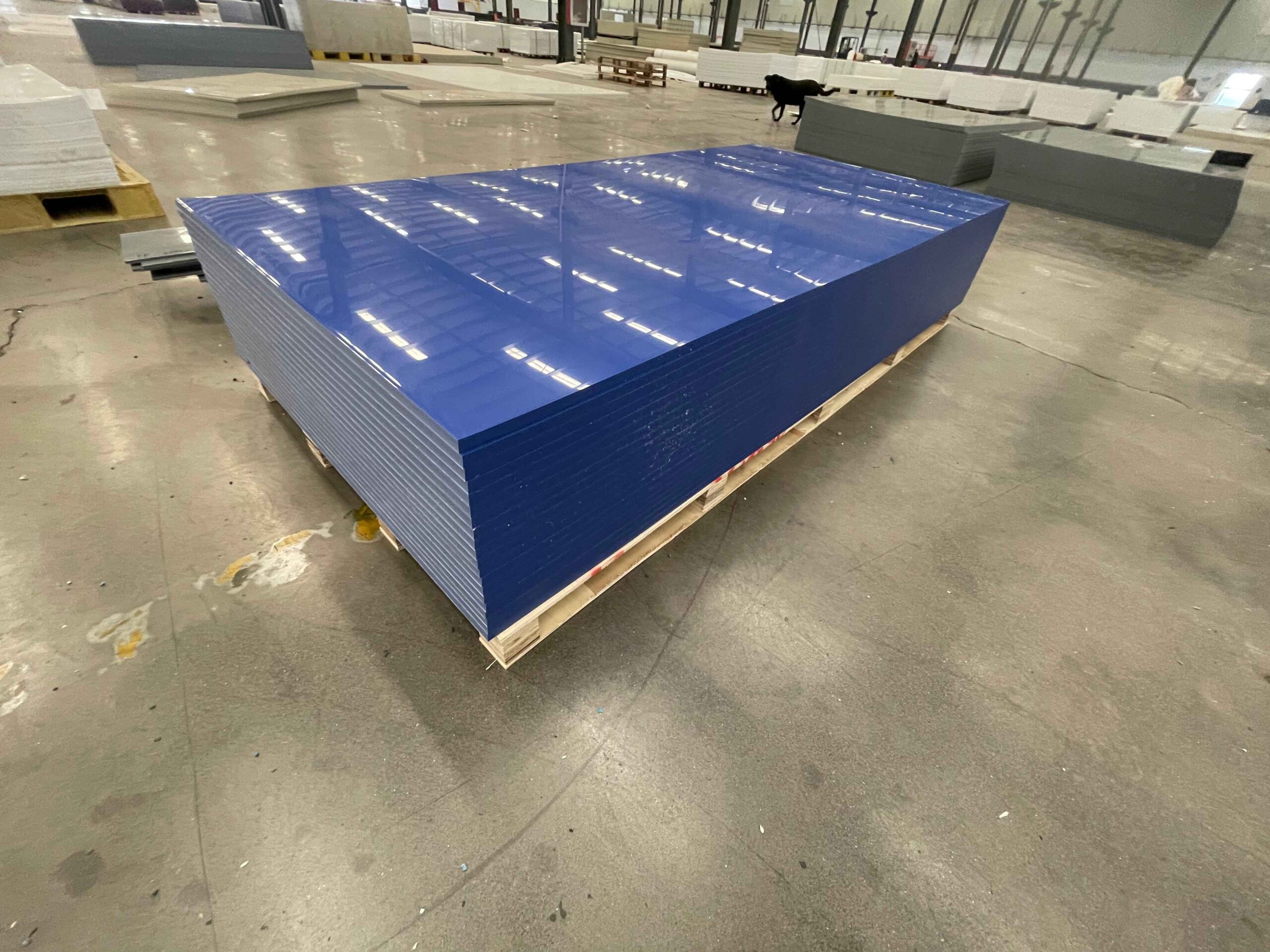

| Panel size | Common: 1220×2440 mm / 1500×3000 mm (custom available) |

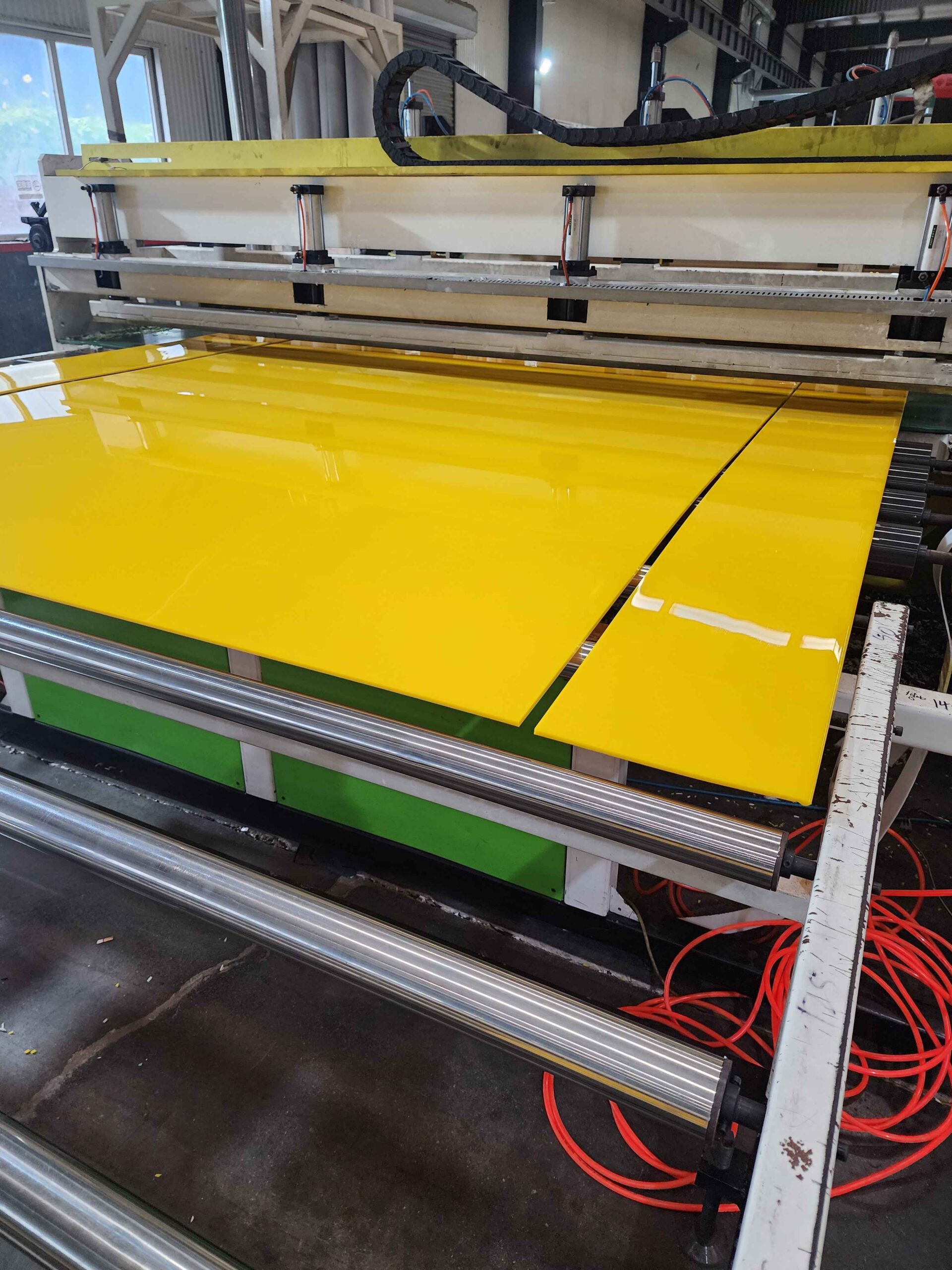

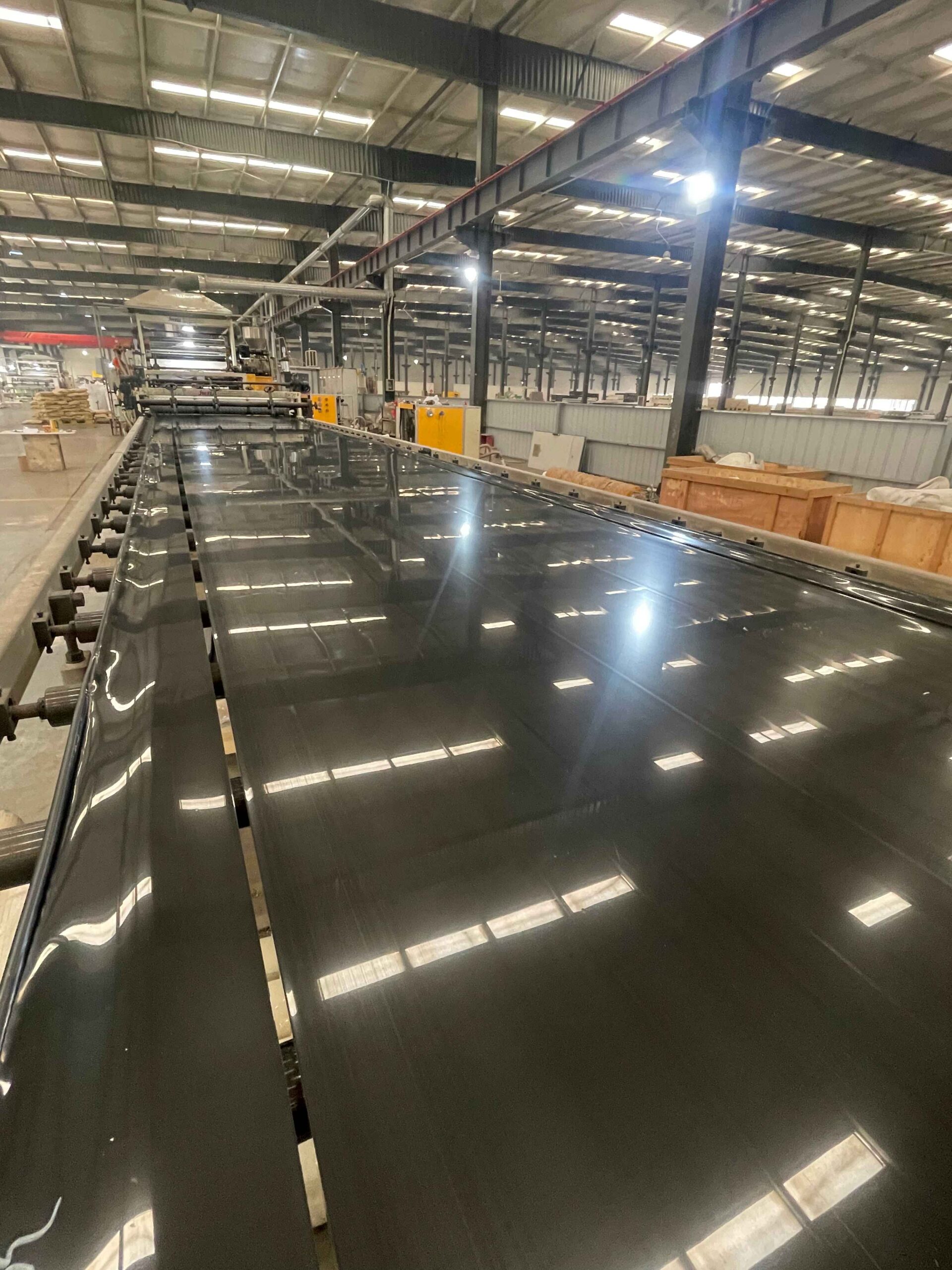

| Surface | Smooth / textured / anti-slip (by request) |

| Color | Black, blue, grey (custom by quantity) |

| Processing | Cut-to-size, drilling, CNC machining, edge finishing |

| Outdoor exposure | Recommend UV-stabilized grade for long-term sunlight |

| Packing | Protective film + pallet/crate for export |

Product Features & Advantages

- Excellent corrosion resistance in marine humidity and salt spray.

- Good toughness for impact and handling on platforms and docks.

- Easy maintenance – does not rust; surface cleans quickly.

- Lightweight compared with many metal panels.

- Long service life when correct grade and thickness are selected.

Typical Applications

- Aquaculture walkways, platform panels and service decks.

- Dock and pier panels, covers and equipment boards.

- Marine fenders, bumpers and protection boards (design-dependent).

- Offshore platform auxiliary panels and corrosion-resistant covers.

- Fish farm equipment components and partitions.

Customization Options

- Anti-slip textures for safer walking surfaces.

- UV-stabilized material and color selection by project.

- Cut-to-size, drilled holes, handles, corner rounding.

- OEM packing and markings for contractors and distributors.

Quality Control & Service

- Thickness and dimensions inspection with tolerances (on request).

- Surface inspection for defects and texture consistency.

- Packing inspection and pre-shipment photos.

- Export documentation support for marine projects.

Ordering Information

- Environment: offshore / coastal / inland aquaculture; UV exposure level.

- Specification: thickness, panel size, surface (smooth/anti-slip), color.

- Installation: connection method and drilling/slot needs.

- Quantity & delivery: order volume, destination and lead time.

- We reply with: recommended grade, MOQ, lead time, packing and factory quote.

FAQ

What makes HDPE “marine-grade”?

Typically it refers to HDPE selected for outdoor UV exposure and marine use conditions. Tell us your environment and we’ll recommend a suitable grade.

Do you provide UV-stabilized sheets?

Yes. UV-stabilized/black UV grade is available for long-term outdoor exposure.

Can you provide anti-slip surface?

Yes. Textured and anti-slip surfaces can be produced for walkway safety.

What thickness is recommended for walkways?

It depends on span, support structure and load. Share your design and we’ll recommend thickness.

Will HDPE swell in water?

HDPE has very low water absorption, so dimensional change is minimal in wet environments.

Can you cut and drill panels for installation?

Yes. We offer cut-to-size, drilling and CNC machining based on drawings.

What colors are commonly used in marine projects?

Black and blue are common; custom colors can be supplied by quantity.

How do you pack for export?

Protective film plus pallet/crate packing suitable for export shipping.

Can you supply to contractors and distributors?

Yes. We support stable supply, OEM packing and project deliveries.

What information do you need for a quote?

Panel size, thickness, surface requirement, quantity, destination and environment details.