Table of Contents

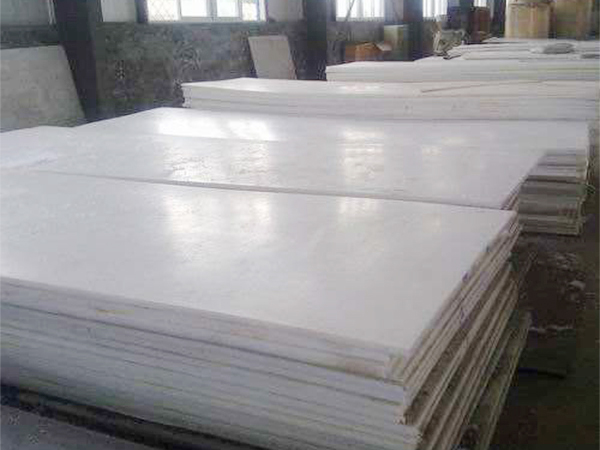

Introduction to UHMW-PE Boards

Ultra-High Molecular Weight Polyethylene (UHMW-PE) boards are advanced engineering plastics known for their exceptional mechanical, chemical, and tribological properties. With a molecular weight typically exceeding 1.5 million g/mol, UHMW-PE is a semi-crystalline thermoplastic that offers superior strength, durability, and wear resistance compared to standard polyethylene. These boards are designed for demanding environments, including high humidity, low temperatures, and corrosive conditions, making them a preferred choice across industries such as material handling, food processing, and pharmaceuticals.

UHMW-PE boards are valued for their self-lubricating, non-stick, and high-impact-resistant properties, which enhance equipment performance and longevity. However, like any material, they have limitations that must be considered. This article explores the properties, applications, comparisons with PTFE, and limitations of UHMW-PE boards, providing a comprehensive guide for engineers, manufacturers, and end-users.

Key Properties and Advantages

UHMW-PE boards exhibit a unique combination of properties that make them ideal for a wide range of applications. Below are their primary advantages:

- Self-Lubrication and Non-Stick Properties: UHMW-PE boards have an extremely low friction coefficient, ensuring excellent self-lubrication and non-stick performance. This reduces material adhesion and wear, making them suitable for friction components like conveyor linings and chutes, even in high-humidity or dusty environments.

- High Impact Resistance: UHMW-PE offers outstanding impact toughness, capable of withstanding strong external forces without cracking. This property is enhanced at low temperatures (down to -176°C), ensuring reliability in cold climates or cryogenic systems.

- Superior Wear Resistance: UHMW-PE’s abrasion resistance surpasses that of standard steel and many plastics, significantly extending equipment lifespan in high-wear applications like silo linings and conveyor systems.

- Excellent Corrosion Resistance: The material resists most acids, alkalis, salts, and organic solvents, ensuring durability in chemical processing and mining. However, it may degrade in highly aggressive acid-alkali environments (e.g., concentrated nitric acid).

- Low Water Absorption: With a water absorption rate of less than 0.01%, UHMW-PE boards remain dimensionally stable in wet conditions, resisting swelling even after prolonged water immersion.

- Low-Temperature Performance: Unlike many plastics, UHMW-PE remains flexible and impact-resistant at sub-zero temperatures, making it ideal for cold storage and outdoor winter applications.

- High Strength and Rigidity: UHMW-PE provides excellent mechanical strength and rigidity, supporting structural applications in high-humidity or moderate-temperature environments.

- Non-Toxic and Safe: Odorless, tasteless, and free of harmful leachates, UHMW-PE complies with food safety and medical standards, making it suitable for food processing and pharmaceutical applications.

Comparison with PTFE Boards

UHMW-PE boards are often compared to Polytetrafluoroethylene (PTFE) boards due to their similar appearance and shared properties. Both are widely used non-metallic engineering plastics, but they differ in key areas:

- Shared Properties:

- Corrosion Resistance: Both materials resist most acids, alkalis, and solvents, making them suitable for chemical environments.

- Self-Lubrication: Both have low friction coefficients, providing excellent self-lubricating and non-stick properties.

- Low Friction: Both are ideal for friction components, reducing wear and energy consumption in sliding applications.

- Differences:

- Wear Resistance: UHMW-PE has significantly higher abrasion resistance than PTFE, making it more durable in high-wear applications like conveyor linings.

- Temperature Resistance: PTFE withstands continuous temperatures up to 260°C, while UHMW-PE is limited to 80-90°C, softening at higher temperatures.

- Impact Strength: UHMW-PE offers superior impact toughness, especially at low temperatures, whereas PTFE is less resilient to impacts.

- Cost: UHMW-PE is generally more cost-effective than PTFE, making it a preferred choice for applications not requiring high-temperature resistance.

Applications of UHMW-PE Boards

UHMW-PE boards are versatile and widely used across various industries due to their robust properties. Key applications include:

- Material Handling and Mining: Linings for coal bunkers, silos, chutes, and hoppers to prevent material adhesion, reduce wear, and improve flow.

- Food and Beverage: Cutting boards, conveyor linings, and equipment components due to their non-toxic, easy-to-clean, and corrosion-resistant properties.

- Pharmaceutical and Medical: Components for medical devices and packaging, leveraging their biocompatibility and chemical stability.

- Marine and Transportation: Wear-resistant linings for docks, truck beds, and self-unloading vehicles to enhance durability and reduce maintenance.

- Chemical Processing: Linings for tanks and pipelines exposed to corrosive chemicals, ensuring long-term reliability.

- Low-Temperature Environments: Components for cold storage, cryogenic systems, and outdoor winter applications due to their excellent low-temperature performance.

Limitations of UHMW-PE Boards

Despite their many advantages, UHMW-PE boards have limitations that must be considered:

- Limited High-Temperature Resistance: UHMW-PE softens and deforms above 80-90°C, making it unsuitable for high-temperature applications, unlike PTFE or nylon.

- Processing Challenges: High melt viscosity due to its high molecular weight requires specialized processing methods (e.g., compression molding or ram extrusion), increasing production costs.

- Lower Rigidity and Hardness: Compared to nylon or polycarbonate, UHMW-PE has lower surface hardness and stiffness, leading to potential deformation or scratching under heavy loads.

- Creep Under Load: UHMW-PE exhibits creep (gradual deformation) under prolonged mechanical stress, affecting dimensional stability in load-bearing applications.

- UV Sensitivity: Without UV stabilizers, UHMW-PE degrades under prolonged UV exposure, causing surface chalking or reduced mechanical properties. UV-resistant additives are needed for outdoor use.

- Limited Corrosion Resistance in Extreme Environments: While generally corrosion-resistant, UHMW-PE may degrade in highly aggressive acid-alkali environments (e.g., concentrated nitric acid), where PTFE performs better.

- Limited Adhesion: The non-stick surface complicates bonding with adhesives or coatings, requiring surface treatments like plasma or corona treatment.

Conclusion

Ultra-High Molecular Weight Polyethylene (UHMW-PE) boards are a industrial-grade material valued for their self-lubricating, non-stick, and wear-resistant properties, as well as their excellent impact toughness, corrosion resistance, and low-temperature performance. These characteristics make them ideal for applications in material handling, food processing, pharmaceuticals, and low-temperature environments. Compared to PTFE, UHMW-PE offers superior wear resistance and impact strength at a lower cost, though it is less suitable for high-temperature applications. However, limitations such as low heat resistance, processing challenges, and UV sensitivity must be addressed to ensure suitability. By understanding these properties and trade-offs, users can leverage UHMW-PE boards to enhance equipment performance and longevity while mitigating potential challenges.

Bulk & Project Supply

- Custom options: thickness, size, color, cut-to-size and CNC machining (by request)

- Quality: stable batches, dimensional checks and surface inspection (records available)

- Packing: film protection, pallet/crate packing, export marking

Get a Factory Quote

Send your material, thickness, sheet size / drawing, quantity and destination. We will reply with MOQ, lead time and a factory quotation.