Plastic products are commonly specified in industrial projects, from packaging and construction to electronics and consumer goods. Although there are various molding techniques, the general manufacturing process typically follows these main stages:

1. Raw Material Preparation

Plastic materials mainly include thermoplastics (e.g., PE, PP, PVC, PS, ABS, PC) and thermosetting resins. These are generally supplied in granule or powder form.

- Additives such as plasticizers, stabilizers, fillers, flame retardants, and pigments may be incorporated to enhance specific properties.

- Before processing, materials are usually dried to remove moisture and prevent defects like bubbles or silver streaks.

2. Plasticizing and Melting

The plastic raw material is heated and sheared in specialized equipment (such as injection molding machines or extruders) until it becomes a viscous molten state. This process is crucial to prepare the material for shaping.

3. Forming Methods (Depending on Product Type)

Different plastic forming techniques are used based on product requirements:

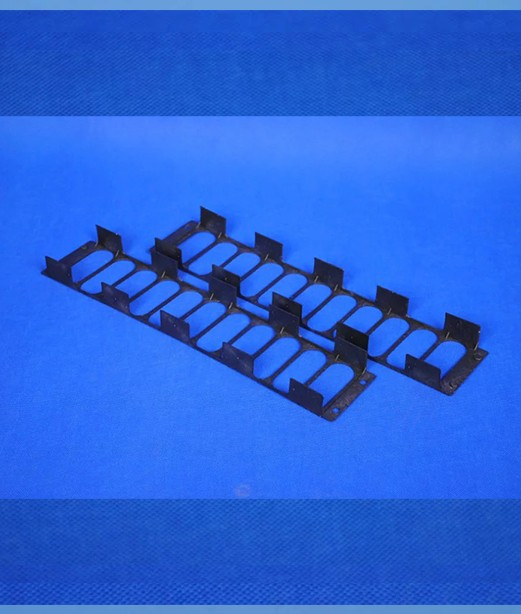

- Injection Molding – Molten plastic is injected into a mold cavity; suitable for complex parts like appliance housings or automotive components.

- Extrusion Molding – Continuous shaping of plastic into profiles like pipes, sheets, or films.

- Blow Molding – Used for making hollow parts like bottles by inflating a hot plastic parison inside a mold.

- Calendering – Produces sheets or films by compressing molten plastic between heated rollers, typically used for PVC films.

- Thermoforming (Vacuum Forming) – Heated plastic sheets are formed over a mold using vacuum; common in packaging trays.

- Rotational Molding, Foaming, etc. – Used for large or lightweight products such as tanks, floats, or insulation materials.

4. Cooling and Demolding

Once the product is shaped, it must be cooled to retain its final form. Cooling methods vary from air cooling to water cooling depending on the process. After cooling, the product is removed from the mold.

5. Trimming and Post-processing

Formed parts may have flash or burrs that need to be trimmed. Additional post-processing like welding, drilling, printing, assembling, or heat treatment may be applied based on the product design.

6. Quality Inspection and Packaging

Finished products undergo quality checks for dimensions, surface appearance, and mechanical properties. Approved items are labeled, packed, and stored or shipped accordingly.

Bulk & Project Supply

- Custom options: thickness, size, color, cut-to-size and CNC machining (by request)

- Quality: stable batches, dimensional checks and surface inspection (records available)

- Packing: film protection, pallet/crate packing, export marking

Get a Factory Quote

Send your material, thickness, sheet size / drawing, quantity and destination. We will reply with MOQ, lead time and a factory quotation.